Below is risk assessment for electrical testing and commissioning that you can use for any kind of project.

Also you will find the standard risk matrix that is also very much useful for conducting the risk assessment.

You can download this risk assessment for electrical testing and commissioning at the end of this page for your reference and submission for client.

| Serial No. | Sub-Activities | Hazards Identified (Generic & Task) | Risks Involved (People & Property) | Risk Rating | Control Measures | Residual Risk | ||

| Severity | Probability | Initial Risk | ||||||

| 1. | Prepare work area | Unauthorized, untrained workers | Cuts Abrasions | 2 | A | L | · TBT/DSTI to be conducted by the foreman/ safety officer prior to work commencement · Task specific safety training to be provided · Authorized personnel to undertake the job · Daily safety inspection should be carried and eliminate the hazard. | Low (ALARP) |

| 2. | Manual Handling | · Incorrect lifting of loads · Sharp edges. · Placing the object while fingers underneath. · Slip/trip/fall ( same level ) · Unsafe posture | · Back Injuries · Cut to finger · Strain · Musculoskeletal Injuries | 3 | C | M | · Any lifting tasks shall be carried out by persons physically capable to do so · No employee should be asked to carry loads above his capacity and in any case no load shall exceed 30kg per man. · Mass of the load is more then to be equally shared · Deploy enough number of personnel for lifting task depending upon the type of load to be lifted. · Use easy mode of transport like trolley etc. · Load not to be lifted above your shoulder height · Keep your fingers away from pinch point while placing the load · Area to be illuminated with adequate lighting. · Proper personal protective equipment’s to be used while manual handling of materials and loads. | Low (ALARP) |

3. | Working with Hand tools ( screw driver, spanner ) | · Slip, trip and fall · Damaged warn out hand tools · Flying objects · Mushroom Heads · Using incorrect type | · Fatigue · Trigger finger · Cuts and abrasions | 3 | C | M | · Defective tools should not be issued or used to perform the task, to be checked by store keeper · Don’t extend the spanner by using a pipe as an extension bar · Hand tools shall be free from oil, grease etc. · Chisel’s head shall have safety cap to avoid finger injury. · Never use a file as a lever · Never use a screw driver as a chisel · Use eye/ face protection when there is flying materials hazard, wear gloves while required to protect the hands · Use right tools for the job | Low (ALARP) |

| 4. | Working with ladder | · Person/ material falling from height · Over reaching · Over loading · Obstructing the access way · Slippery or uneven surface | · Sprain and strain · Fracture · Injury to the person | 3 | C | M | · The ladder should extend minimum one meter from the top for safe movement · Heavy materials should not be carried · Do not erect in slippery, uneven surface should be set up with a 4 vertical to 1 horizontal slope ( 4:1 ) · Inspection and maintenance to be registered and recorded by the store keeper · Step ladder must fully open and lock and the devices to be as per manufacturer · Defective ladder should not be used and report it immediately · Do not work from the top of two rungs · Remember the 3 point contact · Do not work in front of the door. If work is carried then locked the door or blocked off · Ladder to be used for short duration works only limited to 15 min. · Color coded system to be implemented | Low (ALRP) |

| 5. | Working on mobile scaffold | · Uneven surface · Overhead structure and cable · Materials and worker fall from height · Untrained, unauthorized workers · Collapse of scaffold | · Sprain and strain · Fracture · Spinal cord damage · Musculoskeletal Injury · Fatality | 3 | C | M | · Do not stack materials on to the scaffold · Visual inspection should carry before use · Out rigger fitted and breaks are locked on · Only trained scaffolder shall be involved in erection & dismantling activities. · No person to be on the scaffold while it is being moved · Scaffold only use in on level and surface area · Safety harness to be used above 2mtr height and anchored in above shoulder height at all time · Tagging system to be implemented ( i.e., all safe scaffolds shall be provided with green tags and unsafe scaffolds with red tag ) · Keep walkways free of obstacles, tools and equipment · Never stand and sit on the hand rails | Low (ALARP) |

| 6. | Working with electricity | · Electricity · Conductors ( water, metal, concrete ) · Broken wires · Improper plug, case · Overloading | · Electrocution or death · Burns and shocks · Muscle contraction · Heart, lung Paralysis · Fire | 4 | B | M | · Only those persons who have been adequately trained and experienced in the work of electricity to allow for the same. · Electrical work shall not carry out in wet Conditions. · LOTO procedure to be followed during testing & commissioning. · Do not overload to the circuits. · Communicate to all personnel about testing & commissioning. · Don’t use homemade electrical accessories and use industrial type only. · Disconnect main supply before commencing the work. · Defective tools and equipment should not be used, report it and replaced it immediately. · Barricade the location and signage to be placed where circuits and equipment’s are energized. · PPE should be worn at all-time where working in energized circuits. ( Insulated gloves, Electric resistivity shoe ) | Low (ALARP) |

| 7. | Electrical Testing & commissioning using millimeter, insulation tester | · Unauthorized/ untrained Person · Faulty Instrument · Improper identification · Electrocution | · Electric shock and Burns · Cut and abrasion | 3 | B | M | · PTW system shall be applied and implement. · Competent team shall be involved to execute the activities. · Calibrated / certified instrument only shall be used. · Ensure that the circuit is not live before using the instrument. · Emergency procedure shall be briefed to all personnel prior to start the activity. · Emergency evacuation plan shall be readily available according to site condition and briefed to the workforce prior to start. · Emergency contact numbers shall be displayed at work location for easy communication · Trained first aider, fire warden and emergency vehicle to be available at the site during the activity. · Communicate to all personnel about testing & commissioning. · Warning signs and boards should be provided and area to be well barricaded · Appropriate PPE shall be worn at all times. | Low (ALARP) |

| 8. | Working in hot weather | Heat Stress | · Dehydration · Sunburn · Skin Cancer | 2 | B | M | · Drink plenty of water · Employees shall be trained about heat stress symptoms & first aid measures. · Avoid highly physical tasks during the hottest part of the day · Isotonic drinks to be provided · Provide sufficient rest breaks based on the humidity & temperature conditions | Low (ALARP) |

| 9. | While working at night shift | · Poor illumination · Slip/trip/fall | · Fatality · Cuts | 3 | B | M | · Proper illumination to be provided light post to be secured from fall · Proper cable management system to be followed · All materials to be staged in proper manner without obstacles | Low (ALARP) |

| 10. | Work Completion | · Poor housekeeping · Slip/trip/fall | Fire | 2 | A | L | · General housekeeping, Remove all surface, unwanted waste materials from the building · All necessary precautions will be adopted to prevent fire | Low (ALARP) |

Download risk assessment for electrical testing and commissioning

RISK ASSESSMENT FORM Company Group 2 Task Load Test Generator with Load Bank Conducted By (Date) Arasu, Joleen, Yen, Sheng, Thein, Manir Ram, Aye Min, Kelvin and Ramkumar Approved By (Date) Next Review Date 1. Hazard Identification 2. Risk Evaluation 3. Risk Control Reference No. Task Step Hazard Possible Accident/III. INSTRUMENTATION & ELECTRICAL ENGINEERS Gorseinon Road, Gorseinon, Swansea, SA4 9GE Telephone: 02 Fax: 93 Email: info@cpengineering.co.uk www.cpengineering.co.uk Hazard Identification, Risk Assessment & Safe Working Procedure for “Cable Installation, Glanding, Terminating & Testing” Project Title.

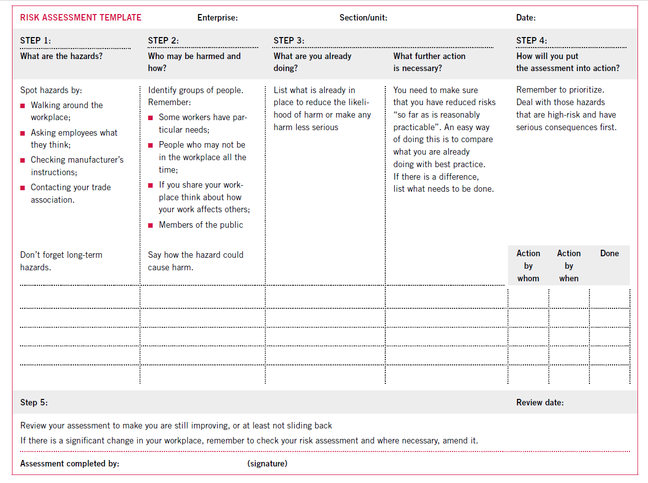

Risk assessments are important as they form an integral part of a good occupational health and safety management plan. They help to: Create awareness of hazards and risks, identify who may be at risk, determine if existing control measures are adequate or if more should be done, they also help to prevent injuries or illnesses when done at the design or planning stage. You may also see Health Risk Assessment Forms

Related:

Project Risk Assessment Form

energy.gov

Project risk assessment form can be used by a structural engineer to assess a project. It outlines a methodology which will be used to qualitatively/subjectively assess a project’s risk. The approach is modeled after project risk assessment processes outlined in standard project management texts and training courses but tailored to the unique risks encountered in a specific project.

Health Risk Assessment Form

michigan.gov

Primary care providers use this form for Healthy Plan beneficiaries enrolled in Managed Care Plans only. Questions are mostly about your current health. Your doctor and your health plan will use this information to better meet your health needs. The information you provide in this form is personal health information protected by law and will be kept confidential.

Basic Risk Assessment Form

hsmc.co.uk

The basic risk assessment form can be used by anyone who wants to start a project. It gives one a general overview of risk assessment and helps one see what a risk assessment form is all about. This form helps you identify some of the hazards in your project and the steps you need to take to control the risks.

Chemical Risk Assessment Form

Free Electrical Risk Assessment Template

utas.edu.au

A chemical procedure risk assessment form must be completed prior to the start of any work involving hazardous chemicals. To complete a chemical procedure risk assessment the assessor must identify: all hazardous substances and dangerous goods used in the procedure, all hazards associated with the chemicals to be used, existing control measures, control measures required before work commences.

Electrical Risk Assessment Form Pdf Format

wagga.nsw.gov.au

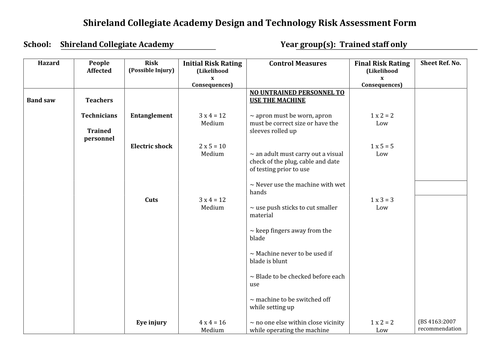

The electrical risk assessment form gives a procedure is to perform electrical risk assessment, which includes a review of the electrical hazards, the associated foreseeable tasks, and the protective measures that are required in order to maintain a tolerable level of risk. This assessment should be performed by electrical engineers before work starts.

Environmental Risk Assessment Form PDF File

york.ac.uk

Environmental risk assessment form is used by environmental management organizations/bodies or project managers. It provides a systematic procedure for predicting potential risks to human health or the environment. The aim of this assessment is to investigate if a chemical is being used or can be used as intended without causing detrimental effects to human health or the environment.

Elopement Risk Assessment Form Word File

whca.org

Elopement risk assessment form is used by nursing homes to determine if a resident has the safety awareness to remain in the facility, an objective, score-based risk assessment should include a defined parameter that indicates an increased risk for elopement and prompts the implementation of prevention strategies. It helps the provider to identify residents who suffer from cognitive deficits that result in poor safety awareness.

Fire Risk Assessment Form

thefpa.co.uk

Fire risk assessment form template follows the preferred five-step method as recommended in guidance in support of the Regulatory Reform (Fire Safety) Order. Ideally suited for simple work premises, It helps one to record fire hazards, assess the risk and evaluate measures to reduce the likelihood of a fire. It is used by personnel rained to assess fire risk.

Gym Risk Assessment Form Word Doc

aisnsw.edu.au

Gym risk assessment form is used by people engaged in fitness businesses. It helps one to identify and assess the significance of potential hazards in the delivery of exercise activities and programs. Prioritising the significance of each hazard allows the opportunity to address the most significant potential risks first.

Job Risk Assessment Form

wcb.yk.ca

A job risk assessment form is intended for use by managers, supervisors, workers and joint health and safety committee members. It outlines the steps in a risk assessment and provides details on completing a job hazard analysis. Effective health and safety management is based on a universal understanding of risks and how to control them through good planning.

General Risk Assessment Form

sodexoremotesites.com

Free Electrical Installation Risk Assessment Template

A risk assessment form is a document that outlines a thorough look at a workplace to identify things, situations, processes, etc that may cause harm, particularly to people. After identification is made, you evaluate how likely and severe the risk is and then decide what measures should be in place to effectively prevent or control the harm from happening. use Self Assessment Forms

- Date of assessment

- Location

- Name f the specific assessment being carried out

- Name and position of the person carrying out the assessment

- Tasks involved in the assessment Identified risks/hazards

- Develop control methods How to implement the control methods

Risk assessments are very important as they form an integral part of a good occupational health and safety management plan. It helps create awareness of hazards and risks. It also helps identify who may be at risk e.g. employees, visitors etc. It also helps in determining control measures.